Competitive PCB Manufacturer

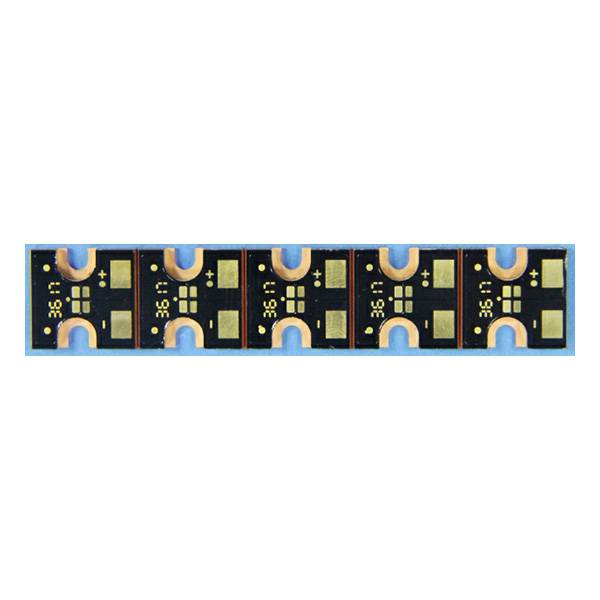

single sided immersion gold Ceramic based Board

Material type: ceramic base

Layer count: 1

Min trace width/space: 6 mil

Min hole size: 1.6mm

Finished board thickness: 1.00mm

Finished copper thickness: 35um

Finish: ENIG

Solder mask color: blue

Lead time: 13 days

Ceramic substrate refers to copper foil at high temperature directly bonded to aluminum oxide (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single or double) special process plate. The ultra-thin composite substrate has excellent electrical insulation performance, high thermal conductivity, excellent soft brazing property and high adhesion strength, and can etch all kinds of graphics just like PCB board, with great current carrying capacity. Therefore, ceramic substrate has become the basic material of high power electronic circuit structure technology and interconnection technology.

Advantage of ceramic based board:

Strong mechanical stress, stable shape; High strength, high thermal conductivity, high insulation; Strong adhesion, anti - corrosion.

◆ Good thermal cycle performance, cycle times up to 50,000 times, high reliability.

◆ The structure of various graphics can be etched as PCB (or IMS substrate); No pollution, no pollution.

◆ The service temperature is -55℃ ~ 850℃; The thermal expansion coefficient is close to silicon, which simplifies the production process of power module.

The application of ceramic based board:

Ceramic substrates (alumina, aluminum nitride, silicon nitride, zirconia and zirconia toughening alumina namely ZTA) due to its excellent thermal, mechanical, chemical, and dielectric properties, is widely applied in the semiconductor chip packaging, sensors, communications electronics, mobile phones and other intelligent terminal, instruments and meters, new energy, new light source, auto high-speed rail, wind power, robotics, aerospace and defense military and other high-tech fields . According to statistics, every year various ceramic substrate value reached tens of billions of market, especially in recent years, with China's rapid development in new energy vehicles, high-speed rail and 5 g base stations, ceramic substrate demand is huge, only in car area, the demand quantity each year is up to 5 million PCS; Alumina ceramic substrate is not only widely used in the electrical and electronic industry, but also in the pressure sensor and LED heat dissipation field .

Maily used in the folljowing 5 arears:

1.IGBT module for high-speed railway, new energy vehicles, wind power generation, robots and 5G base stations;

2.Smart phone backplane and fingerprint recognition;

3.New generation solid fuel cells;

4.New flat plate pressure sensor and oxygen sensor;

5.LD/LED heat dissipation, laser system, hybrid integrated circuit;

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.