Competitive PCB Manufacturer

Rapid Delivery for 9w LED PCB - Low Volume medical PCB SMT Assembly – Kangna

Rapid Delivery for 9w LED PCB - Low Volume medical PCB SMT Assembly – Kangna Detail:

SMT is the abbreviation for Surface Mounted Technology, the most popular Technology and process in the electronic assembly industry. Electronic circuit Surface Mount Technology (SMT) is called Surface Mount or Surface Mount Technology. It is a kind of Circuit assembly technology that installs leadless or short lead surface assembly components (SMC/SMD in Chinese) on the surface of Printed Circuit Board (PCB) or other substrate surface, and then welds and assembles by means of reflow welding or dip welding.

In general, the electronic products we use are made of PCB plus various capacitors, resistors and other electronic components according to the circuit diagram, so all kinds of electrical appliances need various SMT chip processing technology to process.

SMT basic process elements include: screen printing (or dispensing), mounting (curing), reflow welding, cleaning, testing, repair.

1. Screen printing: The function of screen printing is to leak the solder paste or patch adhesive onto the PCB’s solder pad to prepare for the welding of components. The equipment used is screen printing machine (screen printing machine), located at the front end of SMT production line.

2. Glue spraying: It drops glue to the fixed position of PCB board, and its main function is to fix components to the PCB board. The equipment used is the dispensing machine, located at the front end of SMT production line or behind the testing equipment.

3. Mount: Its function is to install surface assembly components accurately to the fixed position of PCB. The equipment used is SMT placement machine, located behind the screen printing machine in THE SMT production line.

4. Curing: Its function is to melt the SMT adhesive so that surface assembly components and PCB board can be firmly adhered together. The equipment used is curing furnace, located at the back of SMT SMT production line.

5. Reflow welding: the function of reflow welding is to melt the solder paste, so that surface assembly components and PCB board firmly stick together. The equipment used is reflow welding furnace, located in the SMT production line behind the SMT placement machine.

6. Cleaning: The function is to remove the welding residue such as flux on the assembled PCB that is harmful to human body. The equipment used is the cleaning machine, the position can not be fixed, can be online, or not online.

7. Detection: It is used to detect the welding quality and assembly quality of the assembled PCB. The equipment used includes magnifying glass, microscope, on-line testing instrument (ICT), flying needle testing instrument, automatic optical testing (AOI), X-ray testing system, functional testing instrument, etc. The location can be configured in the appropriate part of the production line according to the requirements of the inspection.

8.Repair: it is used to rework the PCB that has been detected with faults. The tools used are soldering irons, repair workstations, etc. The configuration is anywhere in the production line.

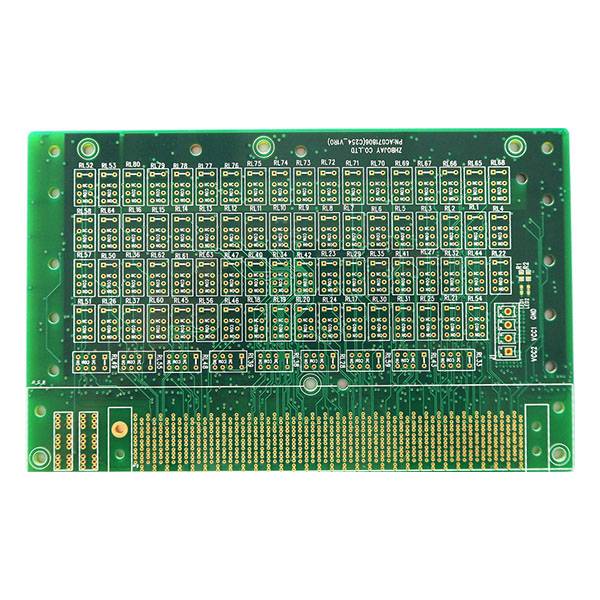

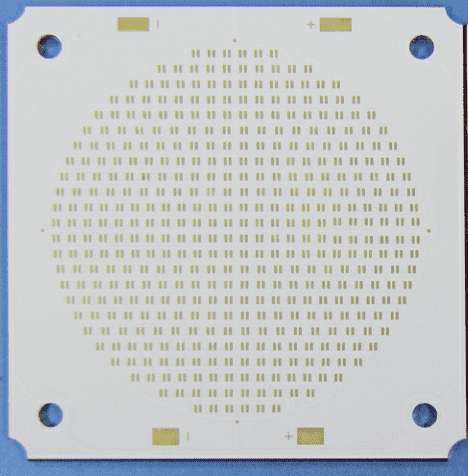

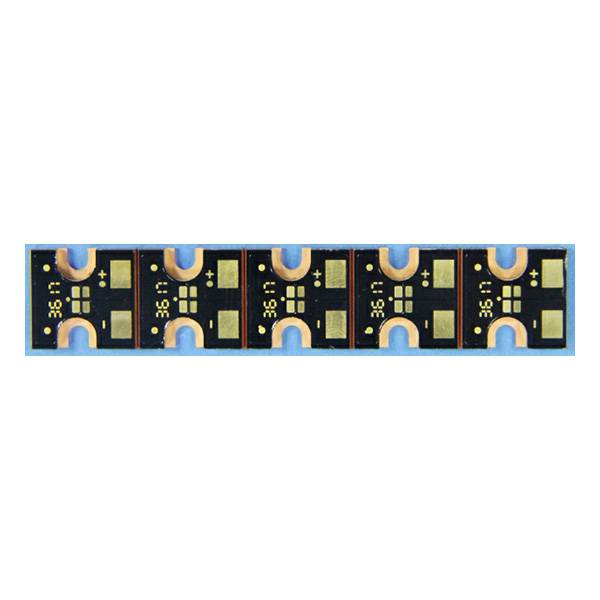

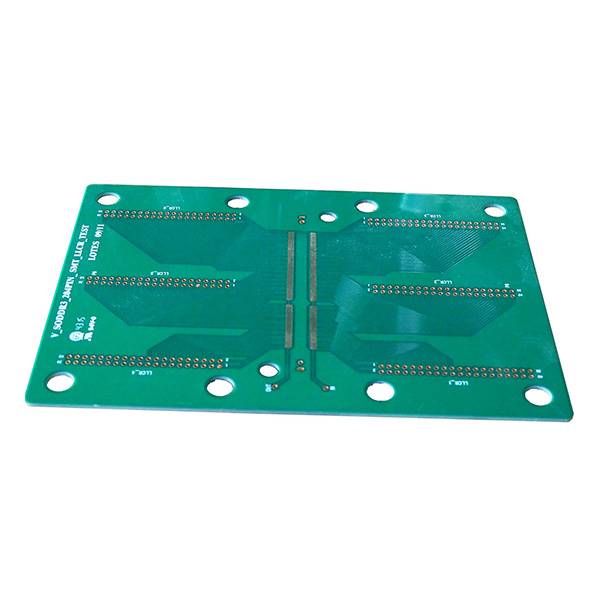

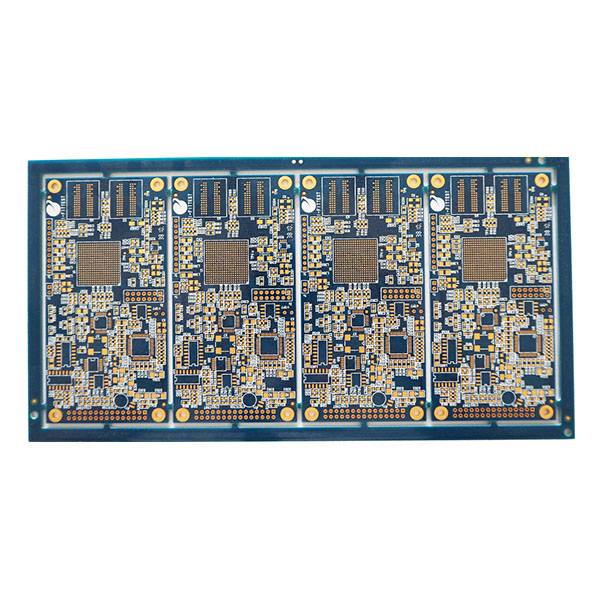

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price competiveness and quality advantageous at the same time for Rapid Delivery for 9w LED PCB - Low Volume medical PCB SMT Assembly – Kangna , The product will supply to all over the world, such as: St. Petersburg, Kenya, belarus, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.