Competitive PCB Manufacturer

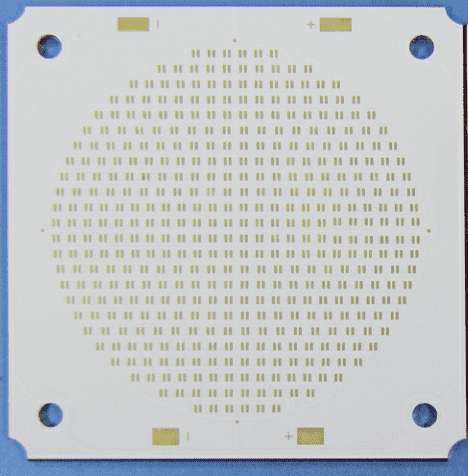

5.0W/M.K High Thermal Conductivity MCPCB For landscape light

Introduction of MCPCB

MCPCB is the abbreviation of Metal core PCBs, including aluminum based PCB,copper based PCB and iron based PCB.

Aluminium based board is the most common type. The base material consists of an aluminum core ,standard FR4 and copper. It features a thermal clad layer that dissipates heat in a highly efficient method while cooling components . Currently, Aluminum Based PCB is regarded as the solution to high power. Aluminium based board can replace frangible ceramic based board, and aluminum provides strength and durability to a product that ceramic bases cannot.

Copper substrate is one of the most expensive metal substrates, and its thermal conductivity is many times better than that of aluminum substrates and iron substrates. It is suitable for highest effectively heat dissipation of high frequency circuits, components in regions with great variation in high and low temperature and precision communication equipment.

Thermal insulation layer is one of the core parts of copper substrate, so the thickness of copper foil is mostly 35 m-280 m, which can achieve a strong current-carrying capacity. Compared with aluminum substrate, copper substrate can achieve better heat dissipation effect, so as to ensure the stability of the product.

Structure of Aluminum PCB

Circuit Copper Layer

The circuit copper layer is developed and etched to form a printed circuit, the aluminum substrate can carry a higher current than the same thick FR-4 and same trace width.

Insulating Layer

The insulating layer is the core technology of the aluminum substrate, which mainly plays the functions of insulation and heat conduction. The aluminum substrate insulating layer is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more effectively it is to spread the heat generated during the device operation, and the lower the temperature of the device,

Metal substrate

What kind of metal will we choose as the insulating metal substrate ?

We need to consider the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate.

Normally, aluminum is comparatively cheaper than copper . Available aluminum material are 6061, 5052, 1060 and so on. If there are higher requirements for thermal conductivity, mechanical properties, electrical properties and other special properties, copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

Application of MCPCB

1. Audio : Input, output amplifier, balanced amplifier, audio amplifier, power amplifier.

2. Power Supply: Switching regulator, DC / AC converter, SW regulator, etc.

3. Automobile: Electronic regulator, ignition, power supply controller, etc.

4. Computer: CPU board, floppy disk drive, power supply devices, etc.

5. Power Modules: Inverter, solid-state relays, rectifier bridges.

6. Lamps and lighting: energy-saving lamps, a variety of colorful energy-saving LED lights,outdoor lighting, stage lighting,fountain lighting

8W/m.K high thermal conductivity aluminium based PCB

Metal type: Aluminium base

Number of layers: 1

Surface: Lead free HASL

Plate thickness: 1.5mm

Copper thickness: 35um

Thermal Conductivity: 8W/m.k

Thermal resistance: 0.015℃/W

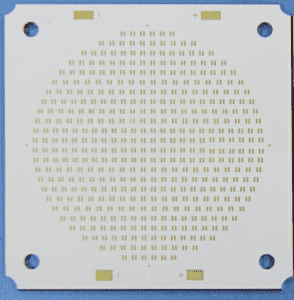

Metal type: Aluminium base

Number of layers: 2

Surface: OSP

Plate thickness: 1.5mm

Copper thickness: 35um

Process type: Thermoelectric separation copper substrate

Thermal Conductivity: 398W/m.k

Thermal resistance: 0.015℃/W

Design concept: Straight metal guide, copper block contact area is large, and wiring is small.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.